Please Choose Your Language

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

TEL : +86-18920692288

Email : dwk0002025@163.com

Views: 0 Author: Site Editor Publish Time: 2025-06-17 Origin: Site

Investing in a CNC sheet metal bending machine is a significant decision for any manufacturing operation. Whether you're a small prototyping shop or a large-scale production facility, choosing the right equipment can make the difference between smooth, efficient workflows and costly downtime. In this comprehensive guide, we'll explore five crucial factors that should guide your purchasing decision. By understanding how material compatibility, processing needs, efficiency versus quality, special process support, and production scale interact, you can select a CNC bending machine that perfectly aligns with your business goals.

CNC bending machines vary significantly in how they handle different metals. Your choice of machine must reflect the types of sheet metal you work with most often:

Carbon Steel:

Strength & Force Requirements — Carbon steel is strong and stiff, requiring higher tonnage and more robust back gauge support.

Tooling Wear — Steel can be abrasive; choose hardened tooling and consider machines with automated tool-changing to minimize downtime.

Springback Compensation — Look for machines offering precise springback correction curves to achieve accurate bends on high-strength steels.

Stainless Steel:

Corrosion Resistance & Surface Finish — Stainless grades demand gentle handling to prevent surface marring. Opt for bending blades with protective coatings or soft-contact options.

Higher Force & Slower Bending Speeds — Expect slower cycle times and greater tonnage requirements due to stainless steel's high yield strength.

Precision Controls — Machines with advanced CNC controls can adapt ram speed and pressure to avoid “ratcheting” or micro-cracking at bend lines.

Aluminum & Lightweight Alloys:

Lower Force + Higher Speeds — Aluminum bends easily, so choose machines capable of high-speed operation with lower tonnage to maximize throughput.

Bend Radius Flexibility — Thinner alloys require careful radius control to avoid cracking; ensure your machine supports adjustable bend radii and soft-touch tooling.

Heat-Sensitive Considerations — Some alloys can exhibit work hardening; CNC systems offering programmable dwell times help relieve stress during bends.

Exotic Materials (Copper, Brass, Titanium):

If your shop fabricates specialty parts, verify that the machine's frame rigidity, hydraulic system responsiveness, and tooling options are rated for these materials' unique elastic and thermal characteristics.

Key Takeaway: Match the machine's tonnage, tooling options, and control sophistication to your primary materials. Overrating capacity wastes investment; underrating jeopardizes part quality and tool life.

Modern manufacturing demands flexibility. A single CNC bending machine may need to process parts ranging from thin gauge LED housings to heavy-duty steel brackets. Consider these capabilities:

Thickness Range:

Minimum & Maximum Gauge — Check the vendor's published charts. A machine rated for 20 mm mild steel may struggle with thin 0.5 mm aluminum without special clamps or safe-bend tooling.

Automatic Thickness Detection — Some CNC systems can auto-sense sheet height, adjusting back gauge positions and ram pressure accordingly.

Bend Length & Width:

Ensure the machine's working length accommodates your longest part.

For wide sheets, confirm adequate beam stiffness and support arms to prevent deflection.

Complex Profiles & Multi-Axis Bending:

Segmented Bending Tools — Look for segmented or multi-tool carriages that enable variable bend radii, offset bends, and compound angles without manual tool swaps.

Rotary & Multi-Axis Capabilities — Advanced models offer rotating heads or additional axes for “box” and “channel” bending, reducing the need for secondary operations.

Program Library & Offline Programming:

A robust CNC control with an intuitive part program library and offline programming software allows engineers to simulate complex bend sequences before loading material, cutting trial-and-error scraps.

Key Takeaway: Prioritize machines with proven adaptability—wide thickness ranges, multi-axis tools, and user-friendly programming—to future-proof against evolving product designs.

High throughput is only valuable if part quality remains consistent. Examine how each machine optimizes both:

Cycle Time vs. Accuracy:

Machines with faster hydraulic pumps and servo-electric crowning systems can reduce cycle times, but verify their repeatability (±0.01 mm is common in precision applications).

Some controls let operators choose “speed” or “precision” modes, trading off a few seconds per bend for sub-millimeter accuracy.

Automated Tool Change & Quick Die Setup:

Automated or semi-automatic tool changers drastically reduce downtime when switching between jobs, boosting net production time.

Quick-change adapters and standardized modular tooling kits support just-in-time manufacturing.

Real-Time Monitoring & Reporting:

Look for CNC controls that log machine utilization, cycle times, and quality metrics. Integrations with MES (Manufacturing Execution Systems) provide visibility into production bottlenecks and scrap rates.

Energy Efficiency:

Modern CNC bending machines use variable-speed hydraulic pumps or fully electric axes to minimize power draw during idle periods, lowering operating costs without sacrificing performance.

Key Takeaway: Seek CNC bending machines that offer selectable performance modes, automated tooling, and real-time analytics to maintain both high throughput and consistent part quality.

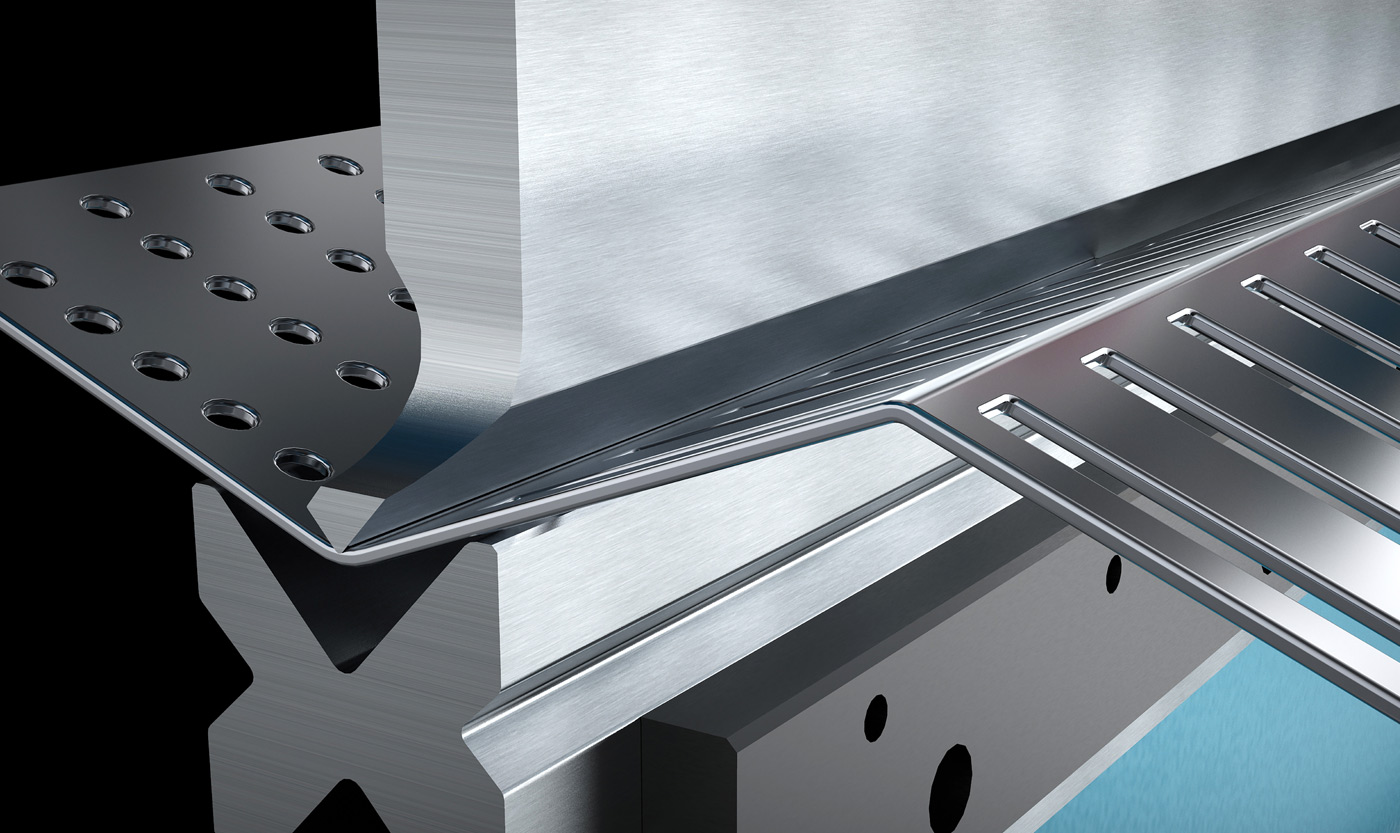

Certain jobs demand exceptional precision or very tight radii. Ensure your CNC machine can handle these niche processes:

Precision & Micro-Bending:

Fine Angle Control — Controls capable of 0.01° or better angular resolution enable micro-bending on thin-gauge parts or decorative profiles.

Adjustable Bend Radius — Programmable crowning and ram cushion settings help achieve consistent inside radii down to material thickness, critical for sealing flanges or decorative edges.

Multi-Stage Bending:

Some parts require incremental bends—partial, dwell, then final bend—to avoid cracking. CNC programs should support multi-stage bend sequences with dwell times and force ramp-up.

Soft-Touch Tooling & Protective Coatings:

For scratch-sensitive surfaces (e.g., architectural aluminum panels), select machines that offer rubber or polymer-coated tooling, ensuring part aesthetics remain pristine.

In-Process Gauging & Feedback:

Advanced systems use laser or force sensors to verify each bend angle and adjust subsequent steps in real time, guaranteeing first-part-right performance even on tight-tolerance aerospace or medical components.

Key Takeaway: If your production includes ultra-precise or micro-bend parts, verify advanced CNC features—high-resolution controls, staged bending sequences, and in-process feedback loops.

Finally, align your machine choice with your shop's volume, product mix, and growth trajectory:

Small-Batch & Prototyping Shops:

A mid-range CNC press brake with quick setup and offline programming capabilities may suffice. Focus on ease of use and flexibility rather than maximum tonnage.

Medium Volume Production:

Look for machines with automated tool changers and higher duty-cycle hydraulics. These features reduce operator intervention and support longer production runs.

High-Volume & Fully Automated Lines:

Consider integrated bending cells combining CNC press brakes with robotic part loading/unloading, automated gauging, and AGV (Automated Guided Vehicle) material handling for lights-out production.

Product Type Considerations:

Large Structural Parts — Prioritize machines with extended bed lengths (4 m and above) and reinforced frames.

Small Precision Components — A compact, high-precision CNC brake with modular tooling racks might be more cost-effective.

Scalability & Future Expansion:

Choose a platform that allows modular upgrades—adding axes, higher-tonnage pumps, or robotic interfaces—so your capital investment can grow with your business.

Key Takeaway: Base your purchase on current and projected production needs. Over-specifying is expensive; under-specifying limits growth. Seek a modular solution that can evolve alongside your operation.

Selecting the right CNC sheet metal bending machine demands careful evaluation of material compatibility, equipment versatility, efficiency versus quality trade-offs, special process capabilities, and alignment with your production scale. By systematically assessing each of these factors, you'll ensure a machine purchase that delivers optimal performance, minimizes downtime, and supports your long-term growth.

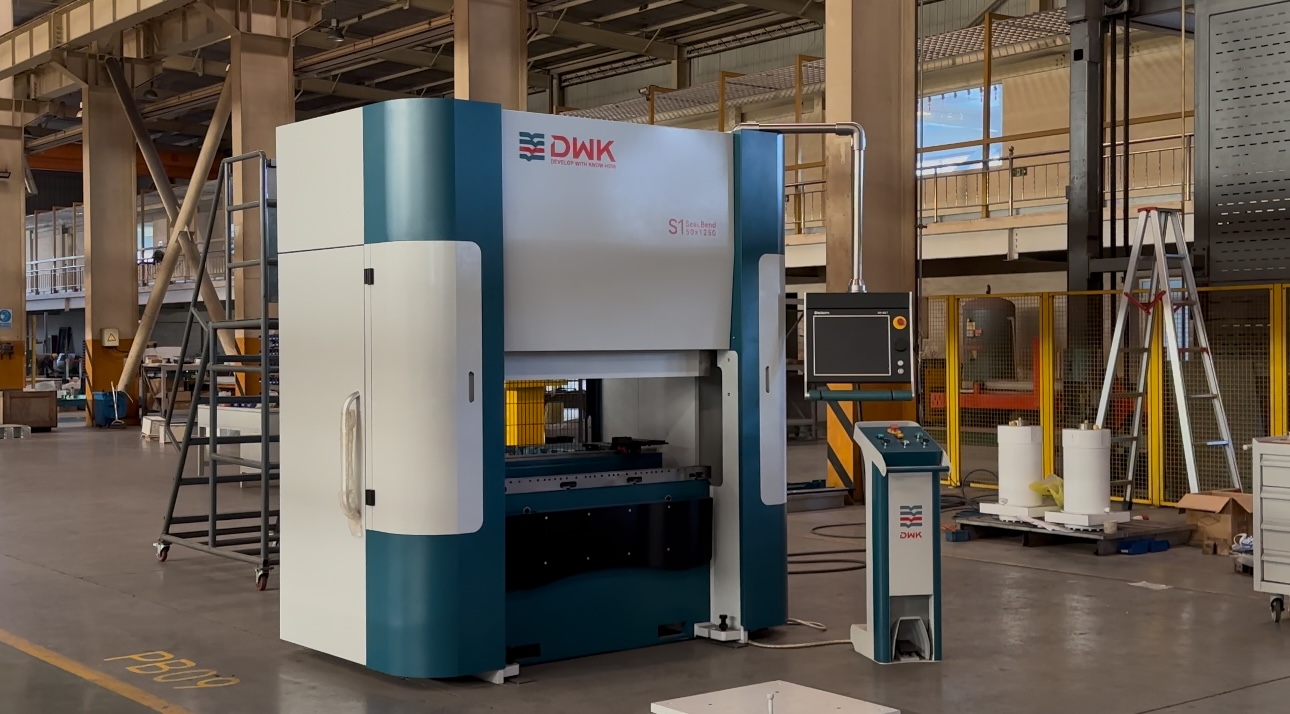

For industry-leading CNC bending solutions designed to meet diverse material challenges and production requirements, consider DWK Machine Tool (Tianjin) Co., Ltd. Their advanced CNC press brakes offer precise control, flexible tooling options, and robust automation features tailored to your specific needs. Visit www.dwkmachine.com today or contact their specialists to discover how DWK can empower your sheet metal fabrication operations.