Please Choose Your Language

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

TEL : +86-18920692288

Email : dwk0002025@163.com

Views: 0 Author: Site Editor Publish Time: 2025-09-29 Origin: Site

In today's fast-paced manufacturing environment, precision and efficiency are non-negotiable. Bending sheet metal into the exact shapes and angles required by modern products—whether automotive frames, appliance housings, or aerospace components—demands advanced equipment capable of high force, repeatable accuracy, and seamless automation. Among the various machines designed for this purpose, the hydraulic press brake stands out as a versatile workhorse. By harnessing the controlled power of hydraulics, it delivers smooth, consistent bends across a wide range of materials and thicknesses.

At its core, a hydraulic press brake is a specialized machine used to bend and form sheet metal by applying controlled hydraulic pressure through an upper tool (punch) onto a lower tool (die). Its primary purpose is to create precise angles and profiles in metal workpieces, ranging from simple flanges to complex, multi-bend geometries.

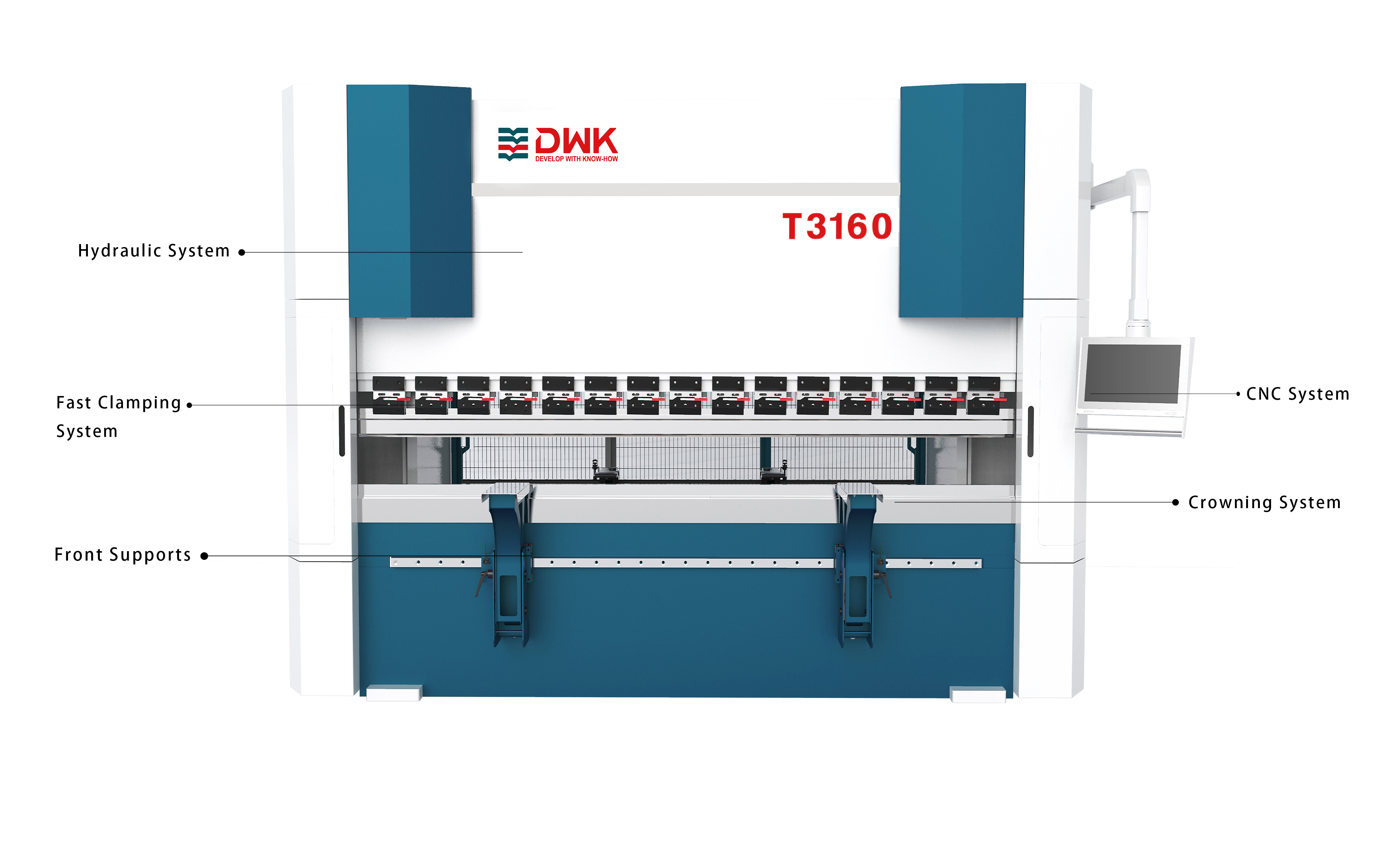

A typical hydraulic press brake comprises:

Frame or Machine Bed: A robust steel structure that supports all mechanical and hydraulic components. It ensures rigidity under high loads to prevent deflection during bending.

Hydraulic System: Includes pumps, reservoirs, cylinders, valves, and pipes. This circuit pressurizes hydraulic oil and transmits that energy to the ram (moving beam).

Ram (Slider): The moving upper beam that holds the punch. As hydraulic cylinders extend, the ram travels vertically to press the workpiece into the die.

Control System: Ranges from simple manual valves on basic machines to fully featured CNC controllers on advanced models. The control system governs cylinder movement, back-gauge positioning, and sequencing for complex bends.

Back-gauge: A programmable positioning device that locates the workpiece accurately for each bend. Multiple axes on the back-gauge allow for multi-bend parts without manual repositioning.

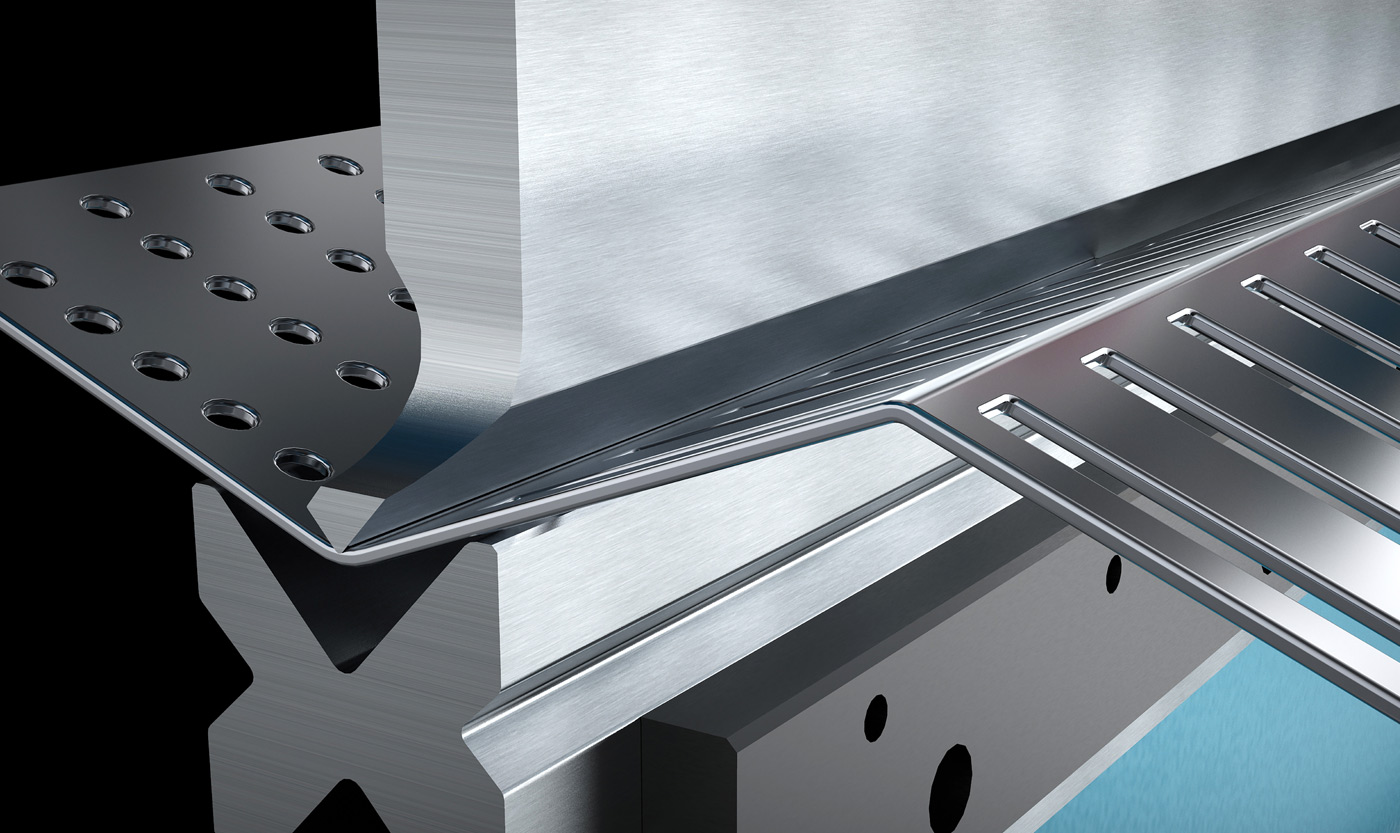

Dies (Tooling): Matched punch and die sets, chosen based on material thickness, bend radius, and angle. Dies come in various profiles—V-dies, U-dies, gooseneck dies, and segmented dies for box bending.

Mechanical Press Brakes use flywheels and mechanical linkages to deliver force. They can achieve very high tonnages but often operate at a fixed stroke profile, making precise control and variable bending speeds more challenging. Mechanical systems also generate more vibration and noise due to clutch engagement.

Electric Press Brakes employ servo-motors and ball screws to drive the ram. They offer excellent repeatability and energy efficiency but may lack the raw pulling power needed for thick, high-strength materials. Electric drives excel in light to medium duty applications and provide very fast cycle times.

Hydraulic press brakes strike a balance: they deliver high force throughout the stroke, allow programmable speed and pressure profiles, and provide inherent shock-absorbing characteristics for smooth, quiet operation.

Hydraulic press brakes are available in a variety of sizes:

Tonnage Ratings: From 30 tons for light fabrication up to 1,200 tons or more for heavy plate bending.

Working Lengths: Common ranges span 1.5 meters to 6 meters, accommodating small parts and large panel fabrication alike.

Stroke & Shut Height: Variable stroke depths (80 mm–300 mm) and adjustable shut heights to optimize tooling and material clearance.

These machines see use in industries such as automotive, appliance manufacturing, construction, aerospace, and general metal fabrication, where bending steel, stainless steel, aluminum, and specialty alloys is routine.

Understanding each part's role is key to appreciating the machine's capabilities:

Hydraulic Pump: Often a variable-displacement axial piston pump, it pressurizes hydraulic oil to the required system pressure (commonly 200–350 bar). Variable pumps adjust flow rate based on demand, improving energy efficiency.

Hydraulic Cylinders: Convert pressurized oil into linear force. High-quality cylinders feature honed barrels, chrome-plated pistons, and pre-loaded rod seals to ensure leak-free operation under extreme loads.

Directional Valves route oil to either side of the cylinder, dictating ram up or down movement.

Proportional Valves finely regulate oil flow and pressure, enabling the CNC controller to command exact speeds and force profiles for each bending phase. This is critical for precision work and repeatable results.

Hydraulic oil serves as both the power transmission medium and lubricant for moving components. Regular oil analysis checks for contamination and viscosity changes, while scheduled filter replacements and reservoir cleanings prevent wear on pumps, valves, and cylinders. High-quality oils with anti-foam and anti-wear additives extend component life and maintain consistent performance.

Advanced hydraulic press brakes integrate a CNC control—featuring:

Touchscreen Interface: For easy recipe management and parameter entry.

Part Programming: Offline software converts CAD models or bend tables into machine programs, simulating sequences before actual production.

Multi-Axis Synchronization: Coordinates ram descent with back-gauge axes (X, R, Z1/Z2) to execute complex bends automatically.

Real-Time Feedback: Monitors cylinder position and ram angle, applying corrections on the fly to maintain dimensional accuracy.

Die Clamping & Quick-Change Systems: Hydraulic or mechanical clamping systems allow rapid die swaps, minimizing setup times.

Work Table: Hardened and ground surfaces ensure precise die alignment. Integrated supports or removable supports accommodate large or heavy workpieces.

A hydraulic press brake's operation involves several coordinated steps:

The hydraulic pump draws oil from the reservoir, pressurizes it, and delivers it via control valves to the cylinders. Pressure intensifies until it matches the force required to begin bending the workpiece.

When the operator or CNC program initiates a bend:

Rapid Approach: The ram moves downward at high speed until it nears the workpiece.

Deceleration Phase: Proportional valves reduce flow rate, slowing the ram as it enters the bend zone for precise control.

Bending Stroke: The ram presses the punch into the sheet metal seated in the die, forming the desired angle. The programmable force curve ensures smooth deformation.

Hold (Dwell): The ram holds at full force for a set dwell time to compensate for springback.

Retract: The hydraulic system reverses flow, and the ram returns to its topmost position.

Feedback Loops: Encoders on cylinders and back-gauges provide positional feedback to the CNC. If the actual ram position deviates, the control automatically adjusts flow or pressure.

Springback Compensation: The system measures departure from target angles and adds micro-bends as needed, ensuring first-part accuracy.

Modern machines handle tasks such as:

Back-gauge Positioning: Moves the sheet into place for each bend without operator input.

Die Changing & Tool Offsets: CNC applies tool library offsets automatically.

Multi-Stage Bends: Staged pressure profiling for difficult materials or tight radii.

Batch Production: Recipe recall for instant changeover between different part programs.

Load Sheet: Operator places or a robot feeds the metal blank onto the table.

Program Selection: Operator selects the part program on the CNC interface.

Indexing & Clamping: Back-gauge positions, clamps secure the sheet.

Bend Sequence: Ram executes bends in the programmed order; back-gauge repositions as needed.

Unloading: Finished part is removed, either manually or with robotic automation, ready for secondary operations or shipping.

Hydraulic press brakes deliver multiple benefits that improve throughput, quality, and cost efficiency:

Programmable Force Curves: Fine-tune speed and pressure throughout the stroke for crack-free bends.

Low Vibration: Fluid-power transmission reduces mechanical shock, protecting the frame and tooling.

Consistent Ram Velocity: Smooth acceleration/deceleration eliminates “kickback” at bend start and end.

Wide Tonnage Range: From light gauge to heavy plate, hydraulics deliver full tonnage at any point in stroke.

Versatility: Bend steel, stainless steel, aluminum, copper, and specialty alloys with the same machine—simply adjust pressure settings and tooling.

Variable-Speed Pumps: Draw power only as needed, cutting idle power consumption by up to 50%.

Oil Filtration & Condition Monitoring: Extends component life and reduces unplanned downtime.

Modular Components: Easy replacement of pumps, valves, and cylinders keeps maintenance straightforward.

CNC Integration: Recipe management and automated sequences reduce operator error and training time.

Robotic Cells: Hydraulic brakes serve as the core in fully automated bending lines, enabling lights-out production.

Quick Changeovers: Tool presets and hydraulic clamping minimize setup between batches.

Hydraulic press brakes find application across a spectrum of manufacturing sectors:

Automotive Manufacturing: Precise forming of chassis components, brackets, and exhaust flanges.

Appliance Production: Creation of seamless panels, housings, and reinforcements for refrigerators, stoves, and washers.

Construction & Infrastructure: Fabrication of structural plates, façade elements, and support brackets requiring consistent angles and high strength.

Aerospace & Defense: Ultra-tight tolerance bending of titanium and aluminum alloys for airframe parts and defense equipment.

Electrical & Electronics: Enclosures, racks, and panels that demand scratch-free surfaces and perfect edges.

Each industry places unique demands—varying material grades, batch sizes, and tolerances—yet hydraulic press brakes adapt through customizable tooling, programmable controls, and scalable automation solutions.

A hydraulic press brake is more than just a bending machine; it's a cornerstone of modern sheet metal fabrication. Its combination of raw hydraulic power, precise pressure control, and sophisticated CNC integration empowers manufacturers to produce complex parts with unwavering accuracy and high throughput. Whether you're running small prototypes or high-volume production lines, a hydraulic press brake delivers the versatility, durability, and efficiency needed to stay competitive.

For advanced hydraulic bending solutions, DWK Machine Tool (Tianjin) Co., Ltd. offers a wide range of press brake models, tooling options, and automation integrations tailored to your production requirements. Visit www.dwkmachine.com today or contact DWK's experts to discover how their hydraulic press brakes can optimize your sheet metal processing operations.