Please Choose Your Language

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

TEL : +86-18920692288

Email : dwk0002025@163.com

| Availability: | |

|---|---|

| Quantity: | |

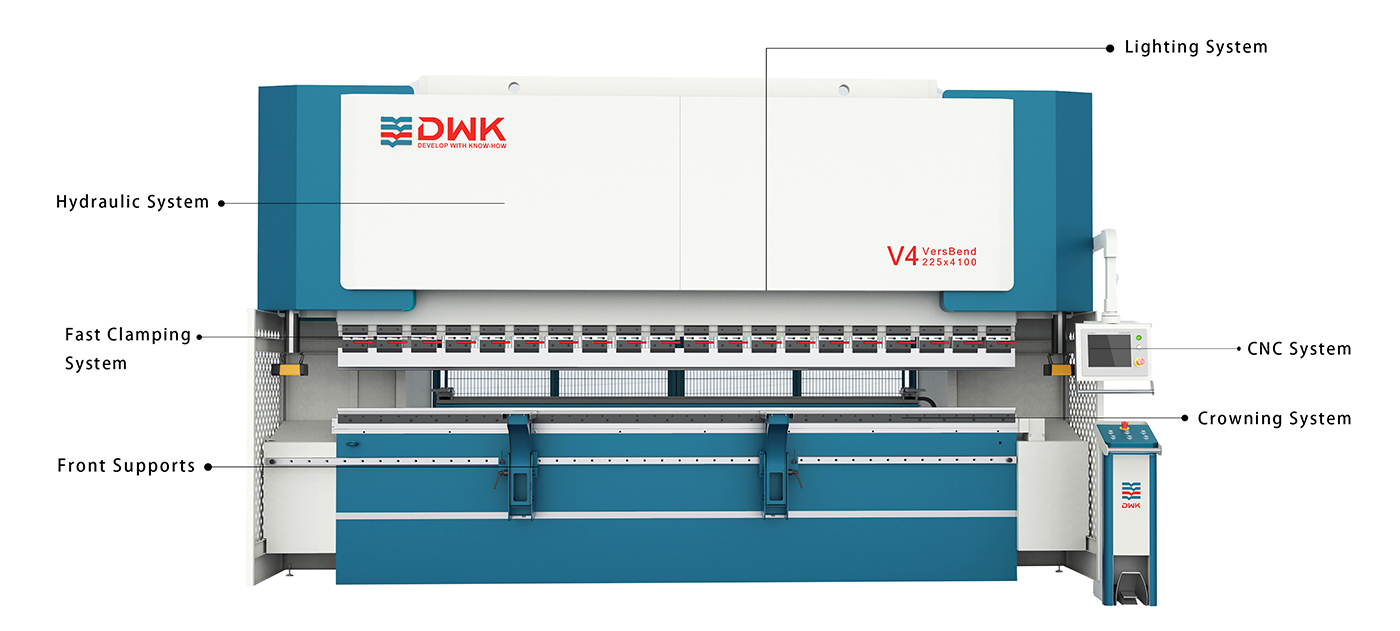

The V4.225-4100 Press Brake is a rugged hydraulic CNC press brake from DWK Machine Tool, engineered for heavy-duty, large-scale metal bending tasks. With a formidable 2250 kN nominal force and 4100 mm bending length, it specializes in processing thick, oversized workpieces—addressing the needs of industries like construction and heavy machinery. Its 3420 mm column spacing eliminates size restrictions for large components, while the optimized hydraulic system ensures stable force delivery during continuous operation. Measuring 5147×1897×3070 mm and weighing 16180 kg, it balances large processing capacity with space efficiency, adapting to diverse factory layouts.

Parameter | Value |

Bending Length | 4100mm |

Nominal Force | 2250kN |

Column Spacing | 3420mm |

Rapid Descent Speed | 180mm/s |

Approach Speed | 10mm/s |

Overall Dimensions (L×W×H) | 5147mm × 1897mm × 3070mm |

Estimated Weight | 16180kg |

The V4.225-4100 Press Brake’s 2250 kN nominal force enables it to bend thick metal sheets (e.g., 15+ mm mild steel) and large structural parts—critical for heavy industrial applications. The 3420 mm column spacing supports oversized workpieces like 4-meter-long roofing sheets or machinery frames, a capability that smaller press brakes lack.

Equipped with a 180 mm/s rapid descent speed and 10 mm/s approach speed, the machine minimizes non-processing time, accelerating production cycles for high-volume tasks. This efficiency is vital for large-scale projects (e.g., mass-producing HVAC ductwork or construction brackets), where reducing lead times directly boosts profitability.

Despite its heavy-duty performance, the V4.225-4100 Press Brake features a streamlined layout that fits standard industrial spaces. Unlike bulky competitors, it requires no extensive factory modifications, making it suitable for facilities balancing large production needs with space constraints.

Weighing 16180 kg, the machine’s rigid frame absorbs vibrations during high-load operations, ensuring consistent accuracy over years of use. Its robust construction reduces maintenance costs and downtime—essential for factories relying on 24/7 production schedules.

The V4.225-4100 Press Brake excels in heavy industrial sectors, including:

Construction: Bending galvanized steel for roofing sheets, large support brackets, and pipeline components (prioritizing durability and weather resistance).

Heavy Machinery Manufacturing: Fabricating frames and structural parts for industrial equipment, tractors, and construction vehicles.

HVAC: Producing large ductwork and vents for commercial buildings (ensuring airtightness and corrosion resistance).

Infrastructure: Creating oversized metal components for bridges, railways, and public works projects (relying on its high force for thick material bending).

DWK Machine Tool implements rigorous quality checks for the V4.225-4100 Press Brake:

High-load stress testing of the frame to confirm it withstands 2250 kN force without deformation.

Pressure verification of the hydraulic system to ensure consistent force delivery and leak prevention.

Safety certification of components (e.g., safety fence, emergency stop buttons) to meet OSHA and CE standards.

Calibration of the CNC system for precise control over large workpiece bending, guaranteeing uniform results.

The 3420 mm column spacing allows the V4.225-4100 Press Brake to handle extra-large workpieces that would be restricted by narrower press brakes—e.g., 4-meter-long roofing sheets or large machinery frames.

Yes. Its 16180 kg frame and robust hydraulic system are designed for 24/7 operation, making it suitable for factories with round-the-clock production demands.

It is equipped with a safety fence, emergency stop buttons, and sensor-based protection—preventing accidents and ensuring compliance with global workplace safety regulations.

Absolutely. With its 2250 kN nominal force and 4100 mm bending length, it easily handles thick galvanized steel—ideal for construction and infrastructure projects.

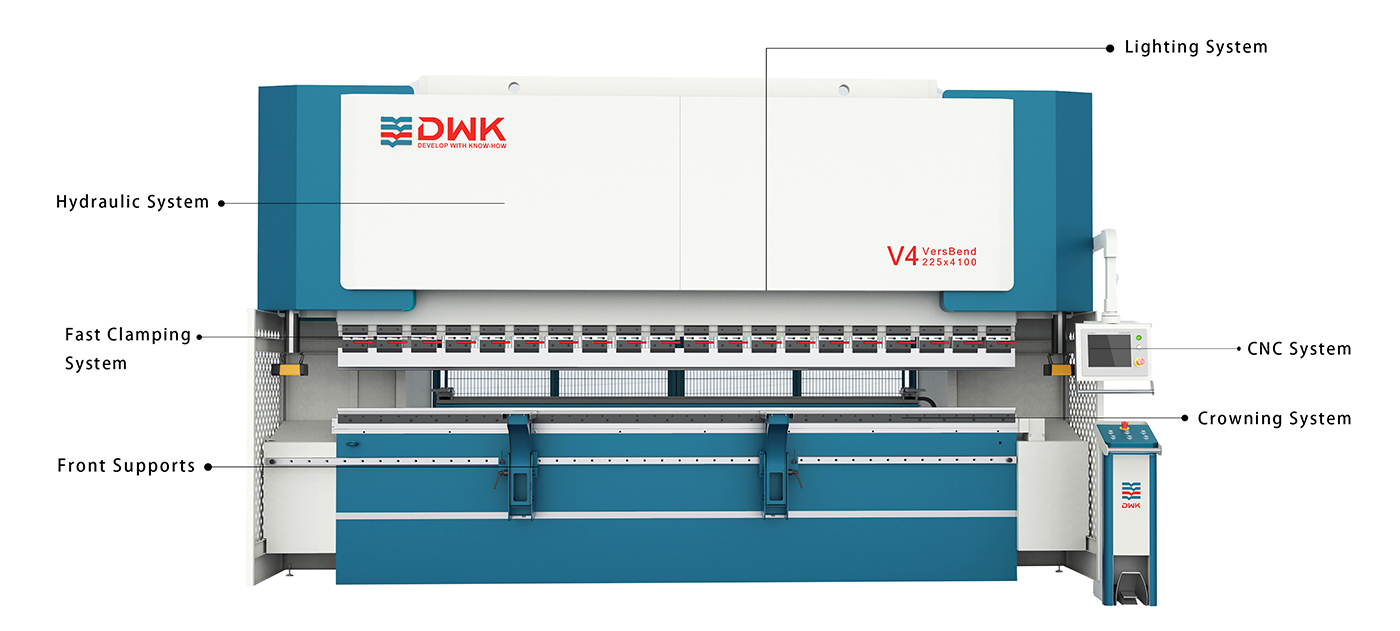

The V4.225-4100 Press Brake is a rugged hydraulic CNC press brake from DWK Machine Tool, engineered for heavy-duty, large-scale metal bending tasks. With a formidable 2250 kN nominal force and 4100 mm bending length, it specializes in processing thick, oversized workpieces—addressing the needs of industries like construction and heavy machinery. Its 3420 mm column spacing eliminates size restrictions for large components, while the optimized hydraulic system ensures stable force delivery during continuous operation. Measuring 5147×1897×3070 mm and weighing 16180 kg, it balances large processing capacity with space efficiency, adapting to diverse factory layouts.

Parameter | Value |

Bending Length | 4100mm |

Nominal Force | 2250kN |

Column Spacing | 3420mm |

Rapid Descent Speed | 180mm/s |

Approach Speed | 10mm/s |

Overall Dimensions (L×W×H) | 5147mm × 1897mm × 3070mm |

Estimated Weight | 16180kg |

The V4.225-4100 Press Brake’s 2250 kN nominal force enables it to bend thick metal sheets (e.g., 15+ mm mild steel) and large structural parts—critical for heavy industrial applications. The 3420 mm column spacing supports oversized workpieces like 4-meter-long roofing sheets or machinery frames, a capability that smaller press brakes lack.

Equipped with a 180 mm/s rapid descent speed and 10 mm/s approach speed, the machine minimizes non-processing time, accelerating production cycles for high-volume tasks. This efficiency is vital for large-scale projects (e.g., mass-producing HVAC ductwork or construction brackets), where reducing lead times directly boosts profitability.

Despite its heavy-duty performance, the V4.225-4100 Press Brake features a streamlined layout that fits standard industrial spaces. Unlike bulky competitors, it requires no extensive factory modifications, making it suitable for facilities balancing large production needs with space constraints.

Weighing 16180 kg, the machine’s rigid frame absorbs vibrations during high-load operations, ensuring consistent accuracy over years of use. Its robust construction reduces maintenance costs and downtime—essential for factories relying on 24/7 production schedules.

The V4.225-4100 Press Brake excels in heavy industrial sectors, including:

Construction: Bending galvanized steel for roofing sheets, large support brackets, and pipeline components (prioritizing durability and weather resistance).

Heavy Machinery Manufacturing: Fabricating frames and structural parts for industrial equipment, tractors, and construction vehicles.

HVAC: Producing large ductwork and vents for commercial buildings (ensuring airtightness and corrosion resistance).

Infrastructure: Creating oversized metal components for bridges, railways, and public works projects (relying on its high force for thick material bending).

DWK Machine Tool implements rigorous quality checks for the V4.225-4100 Press Brake:

High-load stress testing of the frame to confirm it withstands 2250 kN force without deformation.

Pressure verification of the hydraulic system to ensure consistent force delivery and leak prevention.

Safety certification of components (e.g., safety fence, emergency stop buttons) to meet OSHA and CE standards.

Calibration of the CNC system for precise control over large workpiece bending, guaranteeing uniform results.

The 3420 mm column spacing allows the V4.225-4100 Press Brake to handle extra-large workpieces that would be restricted by narrower press brakes—e.g., 4-meter-long roofing sheets or large machinery frames.

Yes. Its 16180 kg frame and robust hydraulic system are designed for 24/7 operation, making it suitable for factories with round-the-clock production demands.

It is equipped with a safety fence, emergency stop buttons, and sensor-based protection—preventing accidents and ensuring compliance with global workplace safety regulations.

Absolutely. With its 2250 kN nominal force and 4100 mm bending length, it easily handles thick galvanized steel—ideal for construction and infrastructure projects.